Industries

Technical Specifications

Applications

Key Features

Industries

- Metallurgical (mining)

- Manufacturing (steel, iron, ceramic)

- Oil/gas petroleum (carbon, carbide materials)

- Academic/Research and Development

- Environmental/Biological

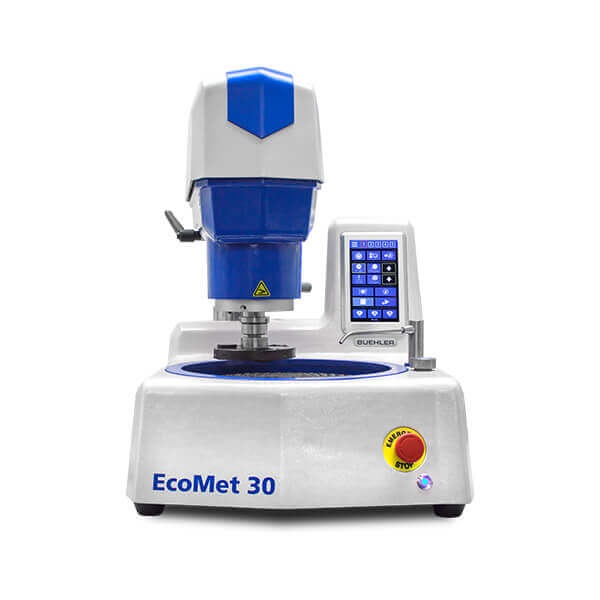

Technical Specifications

- Size of sample: Limited to 15mm height, 25.4cm width and 76.2mm length

- Magnification: 5x, 10x or 50x objective

- Light source: Regular or Polarized

Applications

- Material Science & Engineering – Essential for analyzing material properties, coatings, and surface structures.

- Metallographic Studies – Supports microstructural examination of metals, alloys, and composite materials.

- Quality Control & Inspection – Ensures consistency and precision in manufacturing and research environments.

- Educational & Research Applications – Suitable for laboratory training, professional studies, and advanced microscopy research.

Key Features

- Able to distinguished between non-polarized samples and cross polarization, plane polarized samples.

- X-Polarization & Transmission Imaging – Enhances contrast and detail, making it suitable for examining reflective and transparent samples.

- Up to 50x Magnification – Provides clear and detailed visualization of material microstructures.

- Ergonomic & Safe Design – Integrated handle for easy transport and storage, along with a smooth-edged microscope stage for user safety.

- USB Power Connector – Enables seamless connection with digital cameras for image capture and documentation.

- Student-Friendly Slide Holder – Prevents chipping and ensures stability for precise imaging.

- Energy-Efficient LED Illumination – Provides consistent, cool white light with an extended lifespan, reducing maintenance costs.

- Versatile Condenser System – Supports a wide range of magnifications and contrast techniques, including brightfield and phase contrast imaging.

- Auto Shutoff Feature – Enhances energy efficiency by turning off illumination after two hours of inactivity.

- Durable & Wear-Resistant Construction – Special stage finish protects against friction damage, ensuring long-term reliability.

Testing Process at CarboMat

You can conduct on-site optical microscopy analysis using our high-resolution system Or samples can be submitted with a request form outlining the desired imaging parameters. Our expert technicians will perform the analysis and provide detailed reports based on the microscopic observations.