Transforming Low-Value Materials To High-Value Carbon Products

CarboMat’s Journey in Minutes

Capturing years of hard work and innovation in just a few minutes is no easy task, but this video truly embodies the essence of CarboMat Inc.'s journey. It showcases how we’ve transformed asphaltenes—once considered a waste byproduct of energy production—into affordable, high-performance carbon fiber, driving innovation in industries from aerospace to sports equipment. We’d like to extend our heartfelt thanks to Innovate Calgary and Richard Saad for their close collaboration in bringing our story to life. This video celebrates not only our current successes but also the future of sustainable materials innovation.

Let's talk about the business

CarboMat Inc. was founded in early 2022 as a spin-off from the University of Calgary with the support of the GRInSTEM Fellowship Award from the Global Research Initiative (GRI).

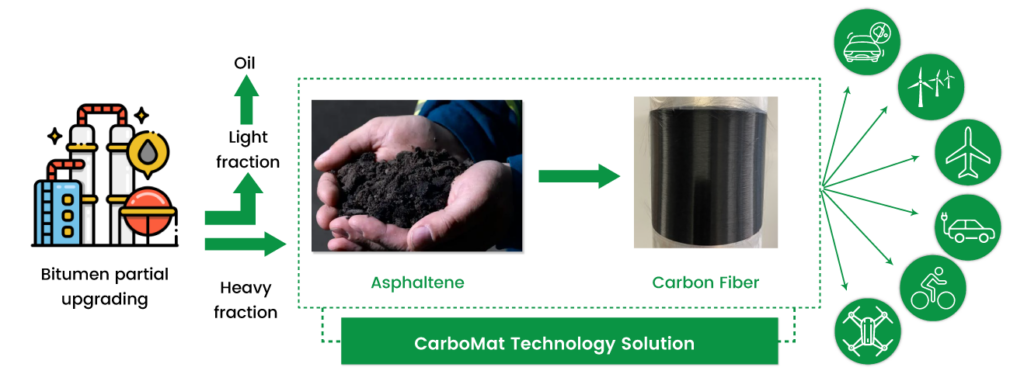

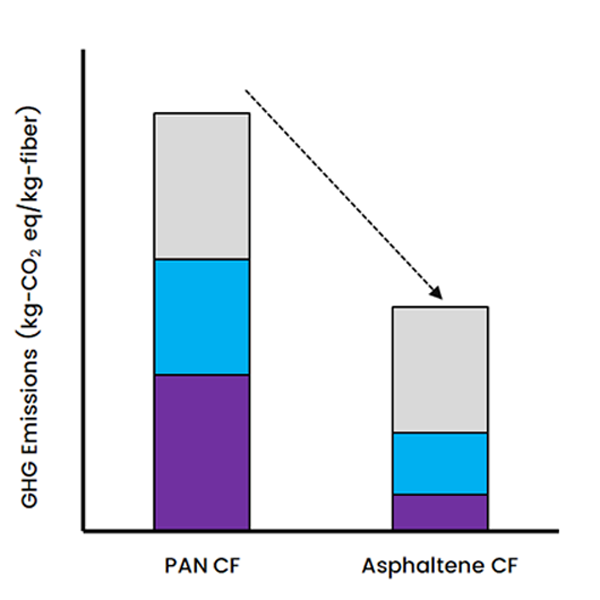

Our business strives to develop a less GHG-intensive technology to produce low-cost and high-value carbon fibers from low-value waste by-products such as oil sands asphaltenes for multifunctional applications in the composite industry (e.g., automotive, sports, leisure, etc.).

Our Value Proposition

The Problem

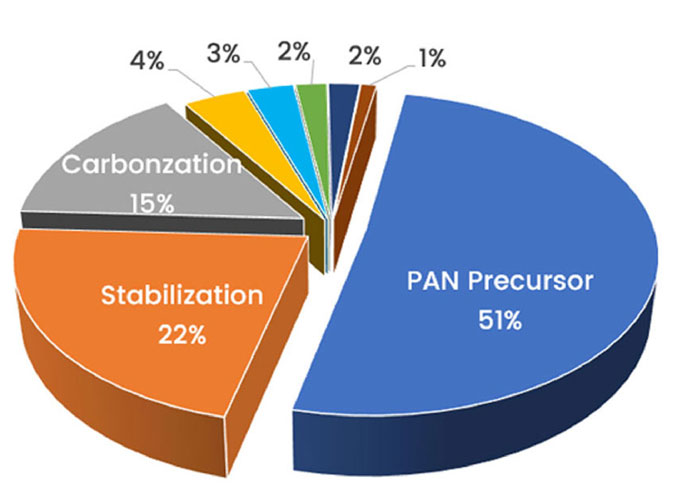

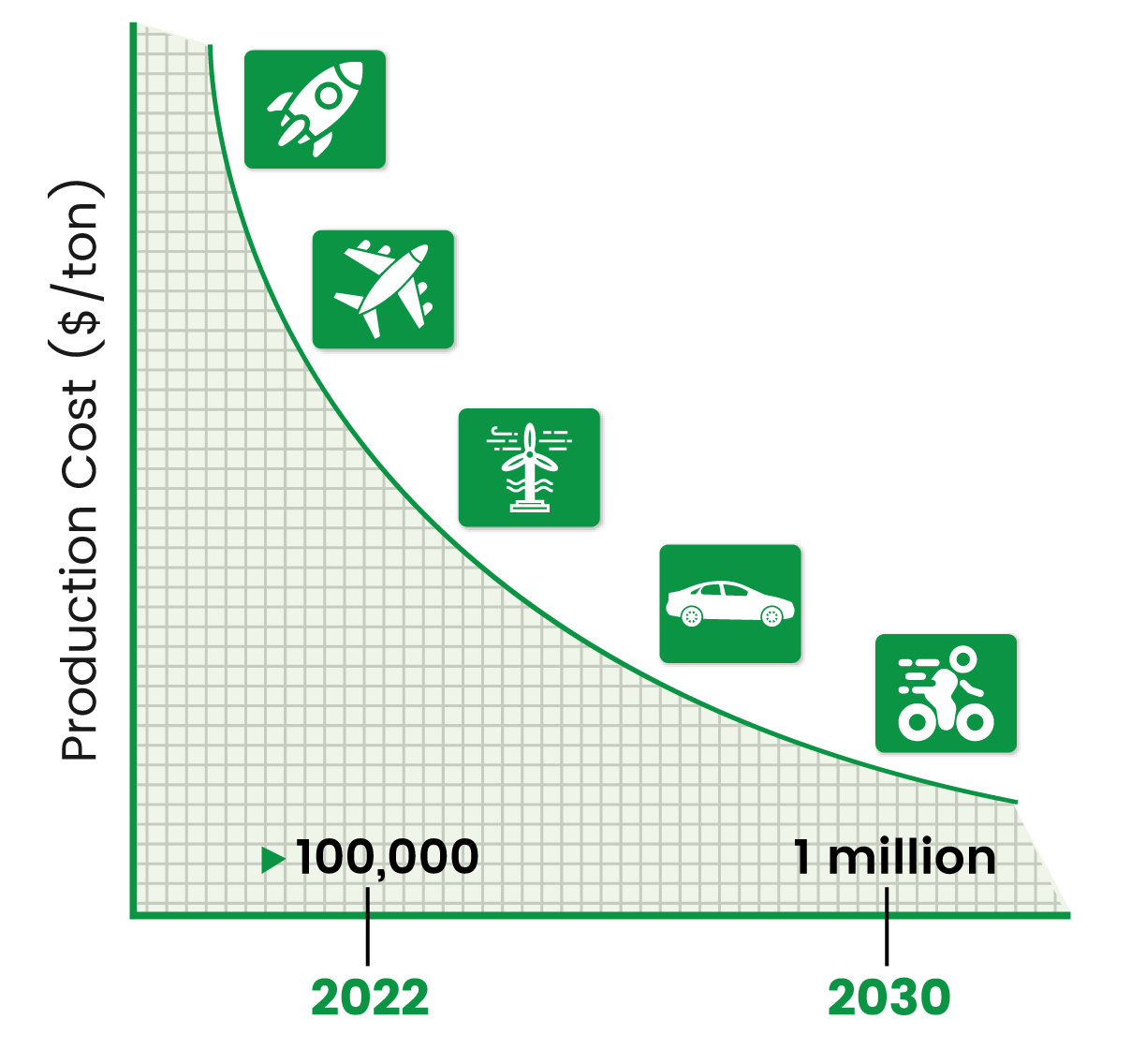

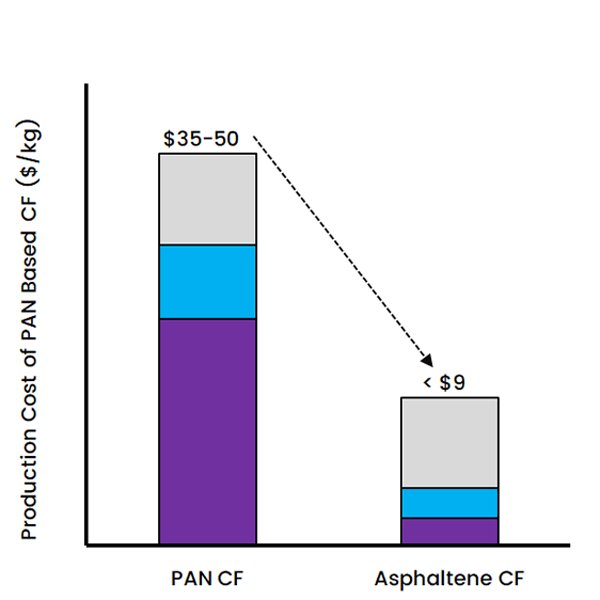

High production cost of PAN-based commercial carbon fibers due to expensive precursor cost.

Production cost share of PAN CF

Mitigation

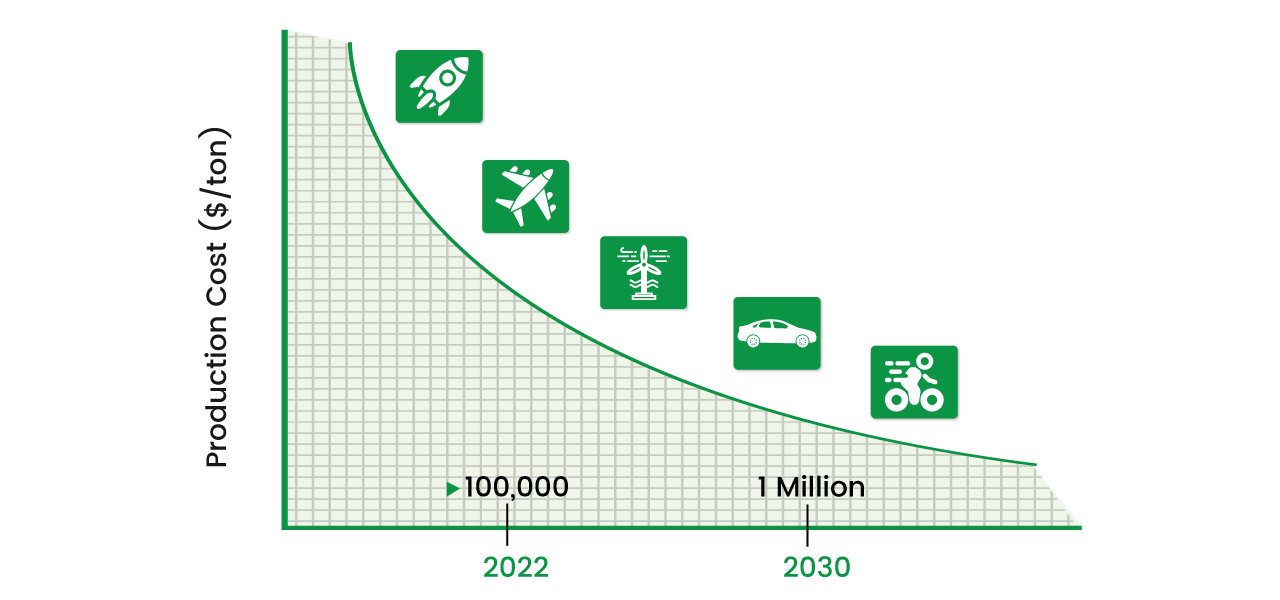

Lowering the carbon fiber production cost facilitates widespread applications of carbon fibers in multiple commercial sectors with reduced costs and higher affordability.

$230/ kg

$115/kg

$27/kg

$25/kg

$15/kg

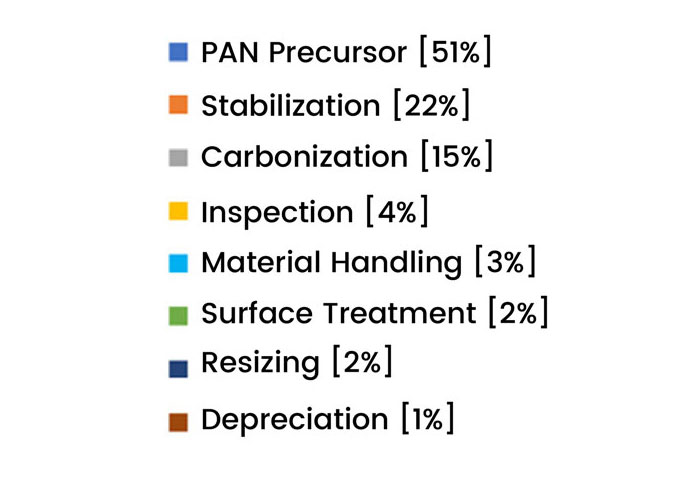

Carbon Fiber Market Projection

Production cost share of PAN CF

$230/ kg

$115/kg

$27/kg

$25/kg

$15/kg

Carbon Fiber Market Projection

Cutting the precursor cost by half will lead to ten-fold increase in market growth

Our Solution: Carbon Fiber from Asphaltene

Paving the way towards lightweight materials

Competitive Advantage of our Technology

Post -Spinning

Spinning

Pre-processing

Post-spinning

Spinning

Pre-processing

~60% decrease in CF production cost with our technology

Post-spinning

Spinning

Pre-processing

Post-spinning

Spinning

Pre-processing

~50% decrease in GHG emissions with our technology

Our Success Pathway

- 100+ Customer Discovery

- 5-10 Strategic Partnerships

- 8 Signed LOIs

CF reinforced bio composites

Proof-of-concept

CarboMat Inc. was formed for business development and commercialization

Received Seed Fund from The University of Calgary, Canada to growth the business.

Concept Feasibility

Scale-up to 10g/day

Proof of concept.

Industry Applications

Composite Material Industry

Automobile Industry

Aerospace Industry

Sports

Leisure