Industries

Technical Specifications

Applications

Key Features

Industries

- Textile Industry

- Materials Research

- Polymer Science

- Quality Control and Product Development

- Carbon Fiber Research

Technical Specifications

- Maximum Temperature: 400°C

- Winding Speed: Up to 700 m/min

- Spinneret Options: 150–500 µm (single-hole and multi-hole configurations)

- Material Capacity: 50g precursor per batch, yielding approximately 20g of green fiber

- Atmosphere Control: Nitrogen (N₂) purging for controlled processing environment

Applications

- Carbon Fiber Development: Producing asphaltene- or pitch-based precursor fibers for high-strength composite applications.

- Materials Science & Polymer Research: Investigating the properties of thermoplastic polymers and optimizing fiber production methods.

- Textile & Fiber Engineering: Developing and testing synthetic fibers such as polyester, nylon, and polypropylene for industrial applications.

- Quality Control & Product Development: Refining fiber manufacturing processes by evaluating consistency, tensile strength, and material properties.

- Aerospace, Automotive & Defense: Exploring advanced fiber materials for lightweight and high-strength applications.

- Industrial Fiber Production Testing – Enables pilot-scale fiber manufacturing for performance evaluation.

Key Features

- Advanced Heating System: Three-zone heating with a high-temperature copper ring block, ensuring uniform polymer melting.

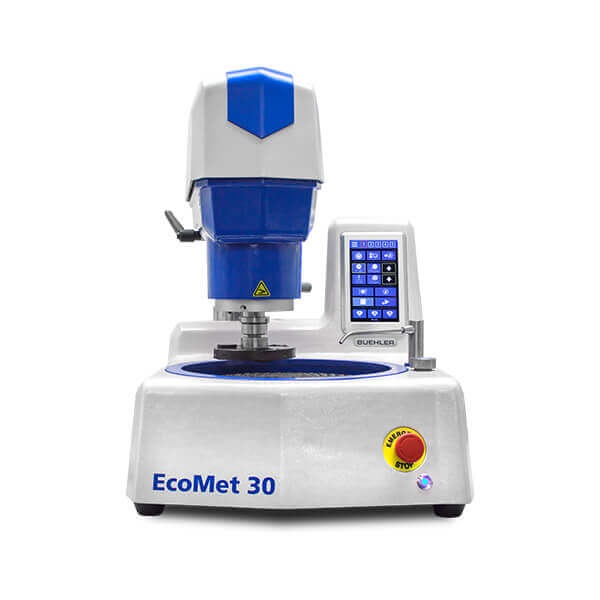

- Precise Control & Monitoring: Touchscreen interface for real-time monitoring of temperature, inert gas pressure, and spinning conditions.

- Stable Inert Gas Pressure: Maintains a controlled environment using nitrogen (N₂) purging for material purity.

- Flexible Spinneret Options: Supports multiple spinneret configurations (single or multi-hole) with diameters ranging from 150 to 500 microns.

- Customizable Winding System: Adjustable winding speed (up to 700 m/min) and a dischargeable winding drum for efficient fiber collection.

- High-Temperature Capability: Barrel temperature reaches up to 400°C, enabling processing of various thermoplastic and precursor materials.

- User-Friendly Operation: Ergonomic design with an organic glass observation window, built-in illumination, and emergency stop function for safety.

- Emergency Safety Features: Equipped with an emergency stop button and independent heating controls for operational safety.

Testing Process at CarboMat

You can schedule on-site testing to operate the AT225 for fiber spinning experiments Or samples can be submitted with a request form specifying fiber composition and desired properties. Our technical team will process the materials and provide analytical reports detailing fiber characteristics and performance.